Progressive cavity pumps have become a vital component in various industries due to their ability to handle a wide range of fluids, including viscous and shear-sensitive substances. To ensure the optimal performance of these pumps, understanding the OEM spare parts is crucial. This guide will delve into the essential aspects of progressive cavity OEM spare parts, their significance, and how to choose the right components.

What are Progressive Cavity Pumps?

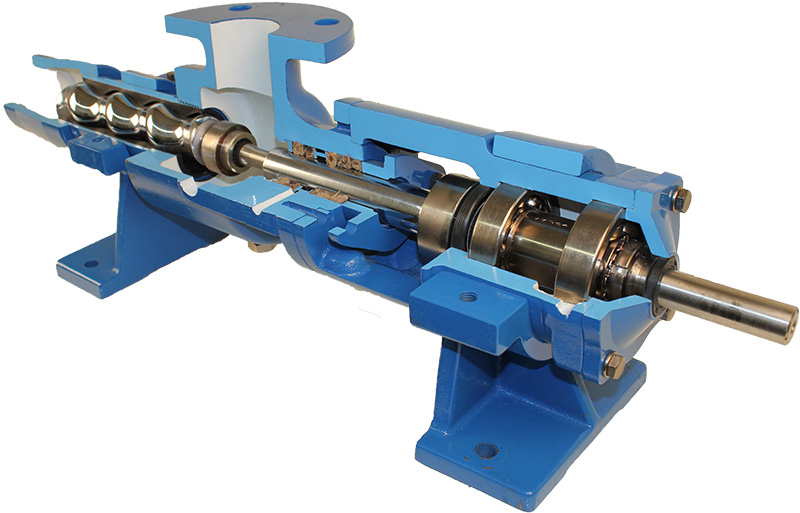

Progressive cavity pumps operate on the principle of a rotating helical rotor within a stator. This design creates a series of cavities that progressively transport fluid from the inlet to the discharge. These pumps are renowned for their reliability and efficiency, making them suitable for applications in wastewater treatment, food processing, and oil extraction, among others.

Importance of OEM Spare Parts

Using OEM (Original Equipment Manufacturer) spare parts is essential for maintaining the integrity and efficiency of progressive cavity pumps. Here are some key reasons why OEM parts are preferred:

- Quality Assurance: OEM parts are designed specifically for the equipment, ensuring a perfect fit and compatibility.

- Performance Optimization: Original parts are manufactured to meet the specific performance standards of the pump, which helps maintain its efficiency.

- Longevity: Using OEM parts can extend the lifespan of the pump, reducing the frequency of replacements and repairs.

- Warranty Protection: Many manufacturers require the use of OEM parts to uphold warranty agreements.

Common Types of Progressive Cavity OEM Spare Parts

Understanding the different types of OEM spare parts available for progressive cavity pumps can help in making informed decisions. Here are some common components:

1. Rotors

The rotor is a critical component that interacts with the stator to create the pumping action. OEM rotors are designed to withstand wear and tear, ensuring consistent performance over time.

2. Stators

The stator works in tandem with the rotor to form the cavities that transport the fluid. High-quality OEM stators are essential for maintaining the pump’s efficiency and preventing leaks.

3. Bearings

Bearings support the rotor and reduce friction during operation. OEM bearings are specifically designed for the pump’s operational requirements, ensuring smooth performance.

4. Shaft Seals

Shaft seals prevent fluid from leaking out of the pump, maintaining efficiency and safety. OEM seals are crafted to provide optimal sealing capabilities, reducing the risk of contamination.

5. Drive Components

Drive components, including couplings and gears, are essential for the operation of the pump. OEM drive parts ensure proper alignment and functionality.

Factors to Consider When Choosing OEM Spare Parts

When selecting OEM spare parts for progressive cavity pumps, several factors should be considered:

Compatibility

Ensure that the parts are compatible with your specific pump model. Refer to the manufacturer’s specifications to confirm.

Quality

Opt for parts that meet industry standards. High-quality materials and manufacturing processes are vital for durability and performance.

Supplier Reputation

Choose reputable suppliers who specialize in OEM parts. Research their reviews and customer feedback to ensure reliability.

Availability

Check the availability of the parts you need. Timely access to spare parts can minimize downtime and keep operations running smoothly.

Conclusion

In summary, progressive cavity pumps are crucial in various industrial applications, and maintaining their efficiency relies heavily on the use of OEM spare parts. By understanding the different types of parts available and considering key factors when making a selection, operators can ensure their pumps continue to perform optimally. Investing in quality OEM components not only enhances performance but also prolongs the life of the equipment, leading to significant cost savings in the long run.