Over the years the basic vortex tube has been used in hundreds of industrial cooling applications. A few have become so popular as to warrant the development of an “applied product” designed to suit the specific application. These products include the Adjustable Spot Cooler, Mini Cooler, Cold Gun and Cabinet Coolers. All of these products can be found in our catalog and on our website.

The Mini Cooler™ is a proven way to reduce downtime and increase productivity on a variety of operations involving small parts where heat is a problem. It evolved out of the garment industry and is commonly used to cool needles and prevent breakage. EXAIR’s Mini Cooler produces a stream of 20°F (-7°C) cold air to prevent heat build-up. The Mini Cooler is particularly effective on high speed operations to prevent burning, melting and heat related breakage. Operation is quiet (76 dBA) and there are no moving parts to wear out.

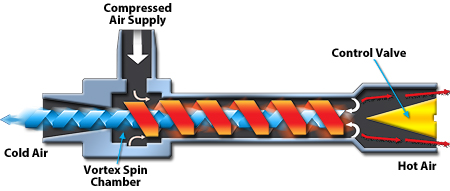

The Mini Cooler incorporated a vortex tube to convert a small amount of compressed air into two low pressure streams, one moving within the other in opposite directions (see below). The two airstreams exchange heat, producing cold air from one end of the tube and hot air from the other. A flexible hose directs the cold airstream at the surface to be cooled.

The Mini Cooler produces instant cold air when compressed air is supplied to it. If less cold air is needed, the volume of cold air can be reduced by regulating the compressed air supply with the pressure regulator. Lower pressure give less cold flow and reduce compressed air consumption.

The Mini Cooler is an excellent spot cooler to prevent burning or breakage. If you have an application and have questions regarding which spot cooler is best for you please contact any of our Applications Engineers . EXAIR has the the expertise and products to provide solutions to your process problems.

Eric Kuhnash

Application Engineer

E-mail: EricKuhnash@exair.com

Twitter: Twitter: @EXAIR_EK