EXAIR’s Super Air Knife utilizes a source of compressed air to create a laminar sheet of high velocity air. This supplied compressed air mixes with ambient air that is entrained into the primary airstream. The Super Air Knife entrains ambient air at a rate of 40:1, making it VERY effective in a variety of drying, cleaning, and cooling applications. Available in lengths ranging from 3”-108” and in a variety of different materials of construction, there’s a Super Air Knife available for just about any application. Any time you have product moving along a conveyor that needs to be cleaned, dried, or cooled off, a Super Air Knife is the ideal fit.

The Super Air Knife is available in aluminum, Type 303 & Type 316 stainless steel, as well as in PVDF with Hastelloy bolts for extremely corrosive applications. While there are numerous options available off the shelf ready to ship same day, not all applications can be served by a stock option. Since EXAIR handles all the manufacturing of these products in our facility in Cincinnati, Ohio, we have a great deal of control over the manufacturing process. If your application cannot accept something right off the shelf, we’re constantly producing special customized knives to fit most requirements.

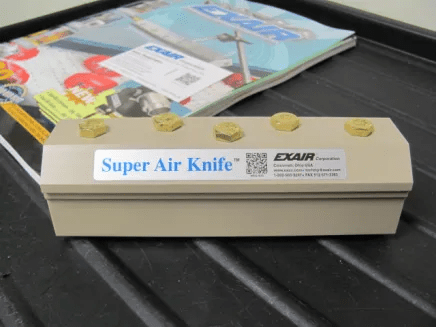

Our knives can be manufactured in a special length if a stock length won’t fit in your application. We’ll use the same design and size profile and can build it to the precise length you require in order to fit perfectly onto your machine. If the dimensional profile of an existing knife isn’t suitable, we can change that too! The Super Air Knife shown below utilizes a very thin design and has been completely modified to achieve the smallest overall profile possible.

All Super Air Knives come stock with ¼ NPT air inlets and ¼-20 tapped holes along the bottom that can be used for mounting. Unfortunately, that isn’t always going to work for every application, so we also manufacture specials with custom air inlets as well as additional mounting holes to fit right onto any custom bracket. The photo below shows a modified stainless steel Super Air Knife with additional mounting holes machined onto either end.

We don’t just offer them in different shapes and sizes as a special, but we’ve also manufactured stock length knives out of entirely different materials. Shown below are two knives of different materials that aren’t already on the shelf. On the left-hand side is a knife manufactured from PVDF and on the right a glass filled PEEK material with brass hardware and a PTFE shim. In this application, the customer was noticing ground interference due to the aluminum knife construction. They specified this particular material, and we were able to machine a knife completely customized for this application.

Every year a new request comes across that is something we haven’t done before. Just because you don’t see it in the catalog doesn’t mean it isn’t possible when you deal with EXAIR. We’re here to make sure you get the most out of our products, and sometimes that isn’t possible right off the shelf. Contact an Application Engineer today if you’d like to discuss your application and begin the process of identifying your next custom solution!

Tyler Daniel, CCASS

Application Engineer

E-mail: TylerDaniel@EXAIR.com

Twitter: @EXAIR_TD