A crowbar is a versatile hand tool known for its strength and durability. Whether you’re prying open crates, pulling out nails, or dismantling structures, a crowbar proves to be an essential tool for various construction and demolition tasks. This article explores the uses of a crowbar, its different types, and how it relates to modern construction materials like geocomposites.

What are the primary uses of a crowbar?

A crowbar is predominantly used for prying, lifting, and demolishing tasks. It is designed to apply leverage to an object, making it easier to break apart materials, remove nails, or lift heavy objects. Common applications include:

- Prying open crates and boxes: The crowbar’s curved end is perfect for slipping under lids and prying them open with ease.

- Removing nails: The claw-like end can be used to pull out stubborn nails from wood or other materials.

- Demolition work: Crowbars are often used to tear down structures, such as walls or flooring, by wedging them into tight spaces and applying force.

- Lifting and positioning: In construction, crowbars can help lift or shift heavy objects slightly to allow better positioning.

What are the different types of crowbars available?

Crowbars come in various shapes and sizes, each designed for specific tasks. Some of the most common types include:

- Flat Crowbar: A flat crowbar has a straight, flat shape with a slight curve at the end. It’s ideal for prying open objects and removing nails.

- Gooseneck Crowbar: This type features a more pronounced curve at one end, which offers greater leverage for heavy-duty prying tasks.

- Wrecking Bar: Larger and more robust, a wrecking bar is designed for heavy demolition work, such as tearing down walls or removing large nails.

- Pinch Bar: This long, straight bar with a pointed end is used for precision tasks, like lifting floorboards or separating tightly fitted materials.

How does a crowbar relate to modern construction materials like geocomposites?

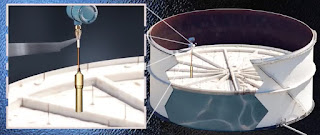

In modern construction, crowbars are often used alongside advanced materials like geocomposites. Geocomposites are multi-layered materials used in civil engineering for drainage, filtration, and reinforcement purposes. When installing geocomposites, a crowbar can be useful for tasks such as positioning the layers, adjusting overlaps, or removing obstructions. The tool’s strength and leverage make it easier to handle these durable materials, ensuring proper installation and long-term performance in construction projects.

What should you consider when choosing a crowbar for your project?

When selecting a crowbar, consider the following factors:

- Material: Crowbars are typically made from steel, which provides strength and durability. Some are coated to resist rust and corrosion, making them suitable for outdoor use.

- Size and weight: The size of the crowbar should match the task at hand. A longer crowbar offers more leverage for heavy-duty tasks, while a smaller, lighter one is easier to maneuver in tight spaces.

- Handle design: Some crowbars come with ergonomic handles for a better grip, reducing hand fatigue during prolonged use.

- Specific application: Choose the type of crowbar that best suits your needs—whether it’s for demolition, prying, or precision work.

A crowbar is an indispensable tool in various construction and demolition tasks, known for its strength, durability, and versatility. Understanding the different types of crowbars and their specific applications can help you choose the right tool for your project. Additionally, in modern construction, crowbars play a crucial role in the installation and handling of advanced materials like geocomposites, highlighting their continued relevance in both traditional and contemporary building practices.