Vortex Tubes are unique items that use an ordinary supply of compressed air to create two streams of air, one hot and one cold. We can drop the temperature by as much as 129oF (71.1oC) below inlet temperature on the cold end. It can also be raised as much as 195oF (107.9oC) above the inlet temperature on the hot end. And this can be done without any moving parts, motors, or Freon. Compressed air would be the only input. In this blog, I will cover how to adjust the Vortex Tubes and the resulting effects.

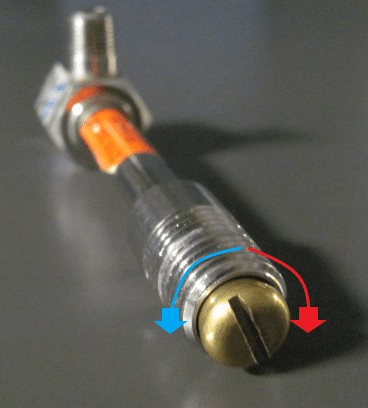

The cold air flow and temperature are easily controlled by adjusting a slotted valve located at the hot air outlet. Opening the valve (turning it counterclockwise) reduces the cold air flow rate and lowers the cold air temperature. Closing the valve (turning it clockwise) increases the cold air flow and raises the cold air temperature. So, how does this apply to cooling?

To go a little deeper, we have to consider cold air temperature and cooling capacity. Cooling capacity is the rate at which heat can be extracted. The higher the cooling capacity, the faster the heat is removed. This deals with temperatures and mass air flow. Like stated above, the colder the air temperature that we create with a Vortex Tube, the less cold air is produced. The two are inversely related. So, we have to find a balance between the temperature and cold air flow. You can find this rate by using Equation 1:

Equation 1:

H’ = 1.0746 * Q * (T2 – T1)

H’ – cooling capacity (BTU/hr)

Q – cold air flow (SCFM)

T2 – Final temperature (oF)

T1 – cold air temperature (oF)

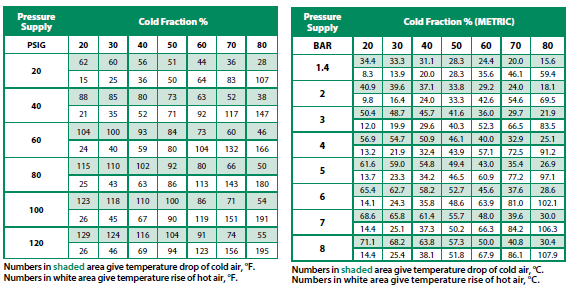

With a Vortex Tube, the temperature difference is based on the inlet pressure and Cold Fraction. The Cold Fraction is the amount of compressed air entering the Vortex Tube that will blow out of the cold end. The remaining portion of the air will travel out of the hot end as heated air. We have a chart below that shows the temperature drop on the cold air side and the temperature rise on the hot air side.

Here’s an example. If we use a model 3240 at two different Cold Fractions, we can see the difference in cooling power. At 100 PSIG (6.9 Bar), the model 3240 will use 40 SCFM (1133 SLPM) of compressed air. If we look at two different Cold Fractions: 20% Cold Fraction and 70% Cold Fraction, we can calculate the cooling capacities by Equation 1. In setting some criteria for our example, we will be using 70oF (21oC) compressed air at 100 PSIG (6.9 Bar). Also, we will have a target temperature of 95oF (35oC).

Example 1: At a 20% Cold Fraction and 100 PSIG, the Vortex Tube will generate a cold air temperature drop of 123oF. So, with a 70 oF inlet air temperature, the cold air temperature will be 70 oF – 123 oF = -53 oF. The amount of cold air at 20% Cold Fraction is 0.2 * 40 SCFM = 8 SCFM. Now that we have this information, we can calculate the cooling capacity.

H’ = 1.0746 * 8 SCFM * (95 oF – (-53 oF)) = 1,272 BTU/hr.

Example 2: At a 70% Cold Fraction and 100 PSIG, the Vortex Tube will generate a cold air temperature drop of 71oF. So, with a 70 oF inlet air temperature, the cold air temperature will be 70 oF – 71 oF = -1 oF. The amount of cold air at 70% Cold Fraction is 0.7 * 40 SCFM = 28 SCFM. Now that we have this information, we can calculate the cooling capacity.

H’ = 1.0746 * 28 SCFM * (95 oF – (-1 oF)) = 2,889 BTU/hr.

As you can see, Example 1 will give you a much colder air stream, but the cooling capacity is 56% less than Example 2. Or, in other words, in one hour, the Vortex Tube that is set at 70% Cold Fraction can remove 2,903 BTU of heat from an object. While the same Vortex Tube set at 20% Cold Fraction, which is much colder, will only remove 1,279 BTU of heat.

In the above examples, we used 95oF as the target temperature for our application. If the target temperature changes, then so does the relative cooling power generated by a vortex tube. We take this into account when we are performing calculations to determine which model and setting for cold fraction would be best for your application.

EXAIR offers a wide range of sizes and cooling capacities with our Vortex Tubes for different applications. They can be used to cool parts, set materials, and regulate temperatures in environmental chambers. They provide an instant and reliable flow of cold air at different temperatures. In this blog, I showed the difference between cold temperatures and the effect of cooling capacity. If you have an application that requires cooling, you can contact an Application Engineer at EXAIR, and we will be happy to run through these calculations to help you select the correct model.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb