Fine Thread vs. Coarse Thread Fasteners

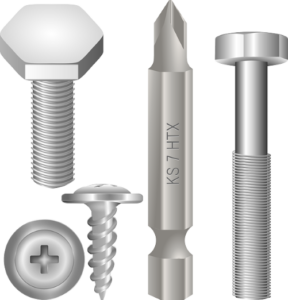

Threading in fasteners plays an important role in the overall function of its application. The recurring question about thread styles is commonly concerned with which one offers more benefit and advantage.

In a broad definition, coarse-thread and fine-threaded fasteners are usually differentiated by distinct features and functions. The wide spaces or height of each thread on coarse threaded fasteners provides great flank engagement and faster installation. While fine threads have a narrow pitch and a larger number of threads which allows a stronger tensile.

Both types of threads on screws or bolts offer a benefit in applications but to ensure stability and safety it’s best to use the right fastener. Prince Fastener is a renowned fastener manufacturer and supplier from China that supply a wide variety of coarse thread or fine-threaded screws, bolts, rods, etc. We also provide custom fasteners according to the specifications of the customer.

Differentiating Coarse Threads and Fine Threads

Coarse Threads

Applications

- Softwood (i.e plywood)

- Oriented strand board

- Wood studs

- Military

- Aerospace

Advantages

- Coarse threads can tap efficiently into brittle or soft materials

- They are preferable in temporary applications since they provide quick installation and disassembly

- Since they have wider thread pitch, they have a larger allowance for coating

- Coarse threads have lesser chances of damage and galling of threads compared to fine-threaded fasteners

Disadvantages

- For a stronger assembly of coarse threaded bolts or screws, a mating nut is used

- Can be prone to loosening wherein vibration is always encountered in the assembly

Fine Threads

Applications

- Hardwood

- Metal applications (like aluminum, titanium, stainless steel, etc.)

- Metal studs

- Other industrial applications

Advantages

- The smaller pitch of fine threads usually has more strength than coarse threads (since it has a larger stress area).

- Fine threads require less torque and eliminate the loosening of components since they can adapt through vibrations.

- Maintains the tightness of joints, hence they’re mostly used in crucial applications like aerospace.

Disadvantages

- The susceptibility to thread galling is more common in fine threads

- With the need for longer engagements in the thread its more likely to encounter damage like nicking and fouling

- Fine threads are less suitable for high-speed applications

Find the Best Threaded Fasteners at Prince Fastener

Prince Fastener carries a wide variation of screws, bolts, nuts, washers, nails, and other fasteners in standard or non-standard. When you are needing to source high-quality fine thread or coarse threaded fasteners, we can supply you with the best products according to specification. We support different kinds of businesses anywhere in the world. We can provide wholesale/bulk products in the factory and competitive prices.

Contact us now to get a free quotation and discover more great deals.