Three Steps to Choose the Right Hydraulic Wrench

Choosing the right hydraulic wrench is very simple, you only need to choose according to three steps. These are bolt size, torque requirements, and space constraints respectively. As long as you strictly follow these three steps to choose, you will be able to find a suitable hydraulic wrench.

Now, TorcStark will introduce these three steps in detail.

1. Bolt size:

There are generally several types of bolts, either metric or imperial. For example, M36, M42, and M48 refer to metric bolts. The hexagonal width of the M36 nut is 55, M42 is 65, and M48 is 75. One type of hydraulic wrench can be selected. If the bolt specification span is too large and the torque span is large, it is necessary to use various types of wrenches to pre-tighten these bolts.

2. Torque requirements:

Bolt specifications and bolt strength grades are the most critical parameters for hydraulic torque wrench selection. Different bolts have different torques. The same bolt has different strength grades and different torques. For the same bolt strength grade, the torque is different in different working conditions. Each industry is different, and the bolt grade strength is different, and the specific situation needs to be treated in detail.

This is the detailed bolt specification introduction

The performance grades of bolts for steel structure connections are divided into more than 10 grades such as 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, and 12.9. Among them, the bolts of grade 8.8 and above are made of low-carbon alloy steel or medium-carbon steel and have been heat-treated (quenched and tempered). They are commonly called high-strength bolts, and the rest are commonly called ordinary bolts. The bolt performance grade label consists of two parts of numbers, which respectively represent the nominal tensile strength value and yield strength ratio of the bolt material.

For example:

The meaning of bolts with performance level 4.6 is:

1. The nominal tensile strength of the bolt material reaches 400MPa;

2. The yield strength ratio of the bolt material is 0.6;

3. The nominal yield strength of the bolt material reaches 400×0.6=240MPa level

Performance grade 10.9 high-strength bolts, after heat treatment, can reach:

1. The nominal tensile strength of the bolt material reaches 1000MPa;

2. The yield strength ratio of the bolt material is 0.9;

3. The nominal yield strength of the bolt material reaches 1000×0.9=900MPa level

The meaning of bolt performance grade is an international standard. Bolts of the same performance grade have the same performance regardless of the difference in their materials and origins. Only the performance grade can be selected for design.

The so-called 8.8 and 10.9 strength grades mean that the shear stress grades of the bolts are 8.8GPa and 10.9GPa

8.8 Nominal tensile strength 800N/MM2 Nominal yield strength 640N/MM2

General bolts use “X.Y” to indicate the strength. X*100=tensile strength of this bolt, X*100*(Y/10)=yield strength of this bolt (because according to the label: yield strength/tensile strength=Y/10)

Such as level 4.8

Then the tensile strength of this bolt is: 400MPa; the yield strength is: 400*8/10=320MPa.

Note: Stainless steel bolts are usually marked as A4-70, A2-70, meaning otherwise explained

Measurement: There are two main units of measurement for length in the world today. One is the metric system, and the units of measurement are meters (m), centimeters (cm), millimeters (mm), etc., which are widely used in Southeast Asia such as Europe, China, and Japan. The other is the imperial system, and the unit of measurement is mainly inches, which is equivalent to the old Chinese market inch, and is widely used in the United States, the United Kingdom and other European and American countries.

1. Metric measurement: (decimal system) 1m =100 cm=1000 mm

2. Inch measurement: (octal system) 1 inch=8 inches 1 inch=25.4 mm 3/8¢¢×25.4 =9.52

3. Products below 1/4¢¢ use numbers to indicate their appellation diameters, such as: 4#, 5#, 6#, 7#, 8#, 10#, 12#

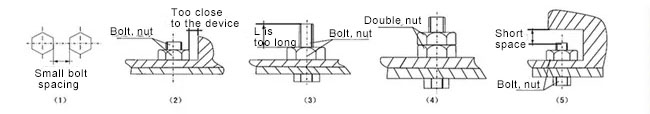

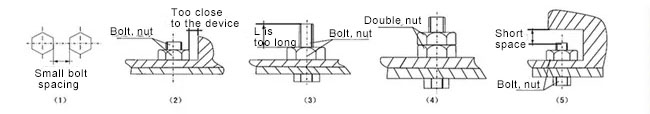

3. Spatial position of bolts and nuts:

Any type of wrench can be used if there is no space restriction. The driven hydraulic wrench is the most versatile; if the thread exposed after the bolt is screwed is long or there is limited space on the bolt, it is best to use a low profile hydraulic wrench; if the distance between the nuts is narrow, a low profile hydraulic wrench can be used.

Space location considerations

Due to the limitation of many factors on site, you should pay attention to the position of the use space when choosing a wrench

Tips: In case of working conditions similar to the above, the low profile hydraulic wrench can be selected when the driving hydraulic wrench cannot work normally.

In the end

The above is a detailed introduction to the three steps of choosing a suitable hydraulic wrench. When selecting a hydraulic wrench, the parameters to be used should be prepared according to the requirements of each step, and then a hydraulic wrench that can meet the parameter requirements should be selected. For very special bolts or working conditions, you can also find a manufacturer to customize a hydraulic wrench. Of course, if you have other questions, welcome to contact TorcStark, we are very happy to provide you with solutions.