Determining the Cost of Compressed Air

When companies are trying to estimate the cost saved using compressed air saving technology such as air saving nozzles, compressed air amplifiers, etc. it is important to know your real compressed air cost. A typical figure used is 30 cents per 1000 cubic feet of air but it can be more in some cases.

To calculate the cost of compressed air in your facility, use the following formula:

COST =

(shaft HP) X (0.746) X (operating hrs) X ($/kW-hr) X (% time) X (% Full Load HP) . Motor Efficiency

The compressor “Shaft horsepower” is frequently higher than the motor nameplate horsepower so you need to check the equipment specification),

Percent time = percentage of time running at this operating level,

Percent full-load shaft HP = Shaft HP as a percentage of full-load Shaft HP at this operating level,

and

Motor efficiency = Efficiency of the electric motor at this operating level.

Determining the Cost of Compressed Air Example

Let’s assume a manufacturing facility has a 100 hp compressor (which requires 110 Shaft HP) that operates for 6,000 hr annually. It is fully loaded 85% of the time (motor efficiency is 95%) and unloaded the rest of the time (using 25% full-load shaft HP and motor efficiency is 90%). The location electric rate is $0.10/kWhr.

Cost when fully loaded will be:

COST = (115 HP) X (0.746) X (6000 hr) X ($0.10/kWhr) X (.85) X (1.0)/.95

= $46.056.00

Cost when partially loaded:

COST = (115 HP) X (0.746) X (6000 hr) X ($0.10/kWhr) X (.15) X (0.25)/.90

= $2,145.00

Annual energy cost = $46,056.00 + $2,145.00 = $48,201.00

Cost per hour = $48,201.00/6000 = $8.00 an hour or $0.13 per minute.

If this compressor generates 425 SCFM which is likely then the cost per cubic feet is:

1000/430 X $0.13 = $0.30 per 1000 cubic feet.

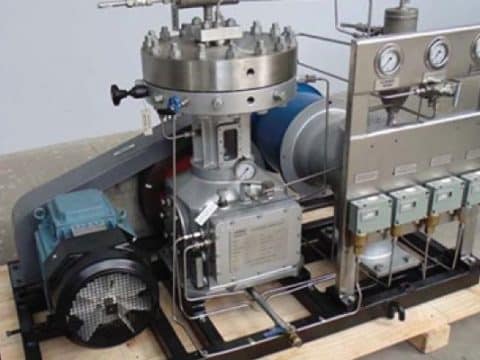

Efficient operation of the compressor is very important to minimize energy cost as well as reducing leaks, and utilizing energy efficient auto drains, filters, tools and air amplifying blow off products and other items to optimize compressed air use.

Nex Flow manufacturers compressed air products for efficient blow off, cleaning, drying, cooling and moving and can assist in the efficient use of compressed air

Compressed air operated air knives are ideal for replacing rows of nozzles or drilled pipe used in blow off applications. What to look for and installation tips are explained here. Nex Flow Air Products are specialists in compressed air applications for blow off, cooling and moving.