In the intricate tapestry of industries, cutting tools emerge as the architects of precision and efficiency. These tools, adept at sculpting metals, woods, plastics, and composites, serve as the foundation of heightened productivity and superior craftsmanship. This article embarks on a comprehensive journey through the realm of cutting tools, exploring their diverse applications and their pivotal role, especially in handling geocomposite materials.

Exploring Cutting Tools

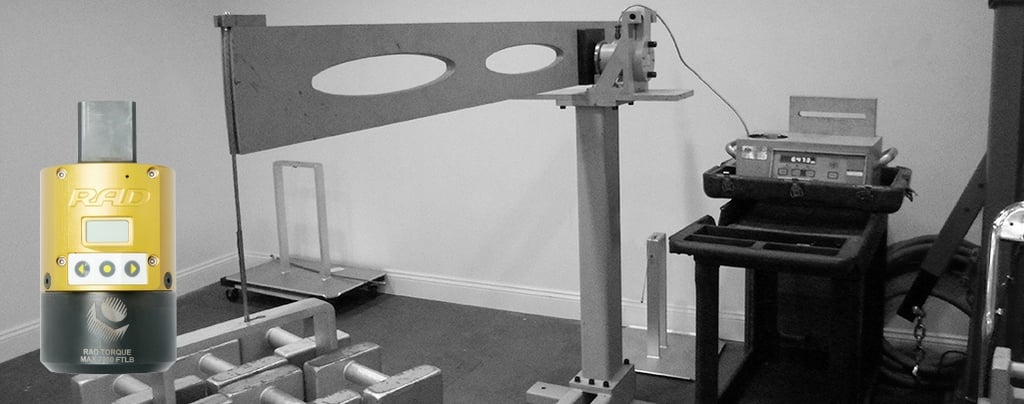

Cutting tools encompass a broad spectrum, ranging from rudimentary hand tools like saws and knives to advanced machinery like lasers, water jets, and CNC machines. Tailored for specific tasks, each tool employs distinct mechanisms and cutting techniques to ensure precise results across various materials.

Varied Types of Cutting Tools

- – Saws: Equipped with toothed blades or abrasive edges, saws adeptly cut through wood, metal, or stone.

- – CNC Machines: Precision-driven, these machines execute intricate cuts based on digital designs.

- – Laser Cutters: High-powered lasers ensure immaculate cuts, especially in materials like metal, plastic, or fabric.

- – Water Jets: Utilizing high-pressure streams mixed with abrasives, they seamlessly cut through materials like stone, glass, and metals.

- – Plasma Cutters: Utilizing ionized gas, these tools slice through electrically conductive materials like steel, aluminum, and brass.

Applications Across Industries

From manufacturing components for automotive and aerospace to cutting concrete for construction, these tools hold pivotal roles in diverse sectors. They are indispensable in textile cutting, ensuring precise patterns, and cater to hobbyists in woodworking and metalworking pursuits.

Cutting Tools and Geocomposites

Geocomposites, vital in civil engineering and environmental sectors, demand precise cutting during installation. Tools such as water jets and CNC machines expertly cut through geomembranes, geotextiles, and geogrids with unmatched precision, ensuring perfect fits for applications in landfills, drainage systems, and erosion control.

Cutting tools epitomize precision and efficiency, crucial in material manipulation across industries. Their adaptability, from crafting intricate components to sculpting geocomposites, solidifies their position as catalysts for productivity and innovation. As technology progresses, cutting tools will continue to lead the charge, meeting diverse industry demands and propelling efficiency.